Proper operation of Burner Tilts on tangentially fired boilers is crucial to controlling fuel combustion and final steam temperature, as well as minimizing NOx formation. Unfortunately, the harsh environment where Burner Tilts reside often makes it difficult to keep them operating freely. High heat, slag/ash build-up, bearing degradation and infrequent preventative maintenance all contribute to rising torque requirements over time.

Proper operation of Burner Tilts on tangentially fired boilers is crucial to controlling fuel combustion and final steam temperature, as well as minimizing NOx formation. Unfortunately, the harsh environment where Burner Tilts reside often makes it difficult to keep them operating freely. High heat, slag/ash build-up, bearing degradation and infrequent preventative maintenance all contribute to rising torque requirements over time.

If left unchecked, one of two things will eventually happen:

- Something mechanical will break or

- The torque requirement will exceed the actuator capacity, leading to stalling and actuator damage.

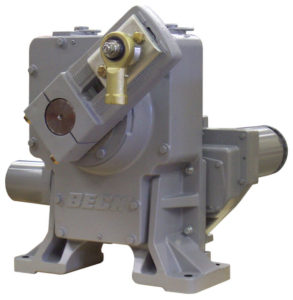

Either case results in a loss of Burner Tilt control which inhibits boiler performance. With installations at over 100 power plants across the USA, Harold Beck and Sons, Inc. has developed a keen understanding of these issues and can offer optimization guidance at no charge.

Actuator issues that emerge on Burner Tilts are usually the SYMPTOM of another problem. Regrettably, some of the most common corrective reactions are actually the least effective and sometimes costly. As an example, one customer ‘brute forced’ the burner tilts with higher torque actuators. Their problem changed from sticky buner tilts to twisted shafts, buckled compartments and 5,000 man-hours of repair labor.

| Corrective action | Pros | Cons |

|---|---|---|

| Restrict overall burner tilt travel by short-stroking the actuator | Prevents burner tilt operation at upper/lower ends where most binding occurs |

|

| Increase actuator torque | Overcomes higher levels of slag/ash build-up, burner tilt stiffness, etc. |

|

Our experience reveals that Beck customers with the fewest Burner Tilt problems share the following characteristics and practices.

- Linkages are optimized for maximum mechanical torque advantage

- Burner tilt mechanisms are cycled routinely to minimize ash/slag build-up

- Bearings are inspected and maintained routinely

- Burner tilt mechanisms and mechanical supports are periodically rebuilt

In addition, Beck recommends the following measures to ensure actuator longevity.

In addition, Beck recommends the following measures to ensure actuator longevity.

- Link Assist™: Beck Sales Engineers offer free site visits to evaluate actuator linkage configurations and recommend optimized setups.

- Torque Sensing: Beck actuators can be built with torque sensing capability that can be used to monitor burner tilt stiffness, develop a torque profile and output over-torque alarms.

- Electronic Stall Protection: Beck actuators are equipped with built-in stall protection to prevent extended stall conditions which leads to actuator damage.

- Remote Electronics are available where excessive temperatures exist.

Contact a Beck Sales Engineer to find out how to get the most out of your Burner Tilts.