EXPLOSION PROOF VALVE ACTUATOR WITH DC POWER OPTIONS

The Group 57 valve actuators are a great choice for valve actuation in remote, hazardous environments. In addition to running on AC power, the group 57 units are also DC powered electric actuators, explosion proof and therefore perfect for situations where explosive gases are present. These valve actuators reset to a fail-safe position during power outages and are great for low power environments such as a gas pipeline using solar power, batteries and fuel cells. Built with your need for flexibility in mind, Beck reliability standards and a rugged construction design for harsh environments.

The Group 57 quarter-turn valve actuator offers the benefit of a smart, feature-rich control package that provides precise positioning, easy setup and configuration, multiple control options, flexible alarming, and diagnostic capabilities.

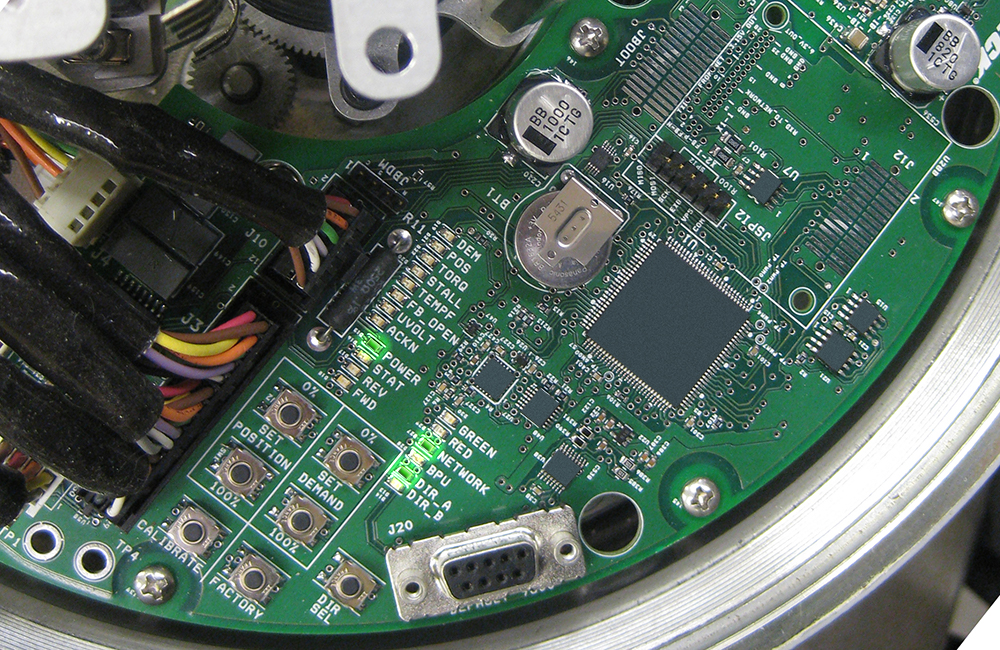

All Group 57 actuators are equipped with Beck’s time-proven Digital Control Module (DCM) technology. The DCM positions the actuator in response to analog, digital or pulse control signals and provides a myriad of configurable functions, features, diagnostics and operating preferences. The actuators are also equipped with a contactless, non-wearing position sensor to monitor the output shaft position for both control and remote monitoring functions.

In modulating applications, the DCM continuously compares the Position signal to the Demand signal and takes the appropriate action to position the actuator’s output shaft as required to within 0.1 degree rotation.

AVAILABLE TORQUE AND TIMING COMBINATIONS FOR THE MODEL 57-109

Beck’s DCM provides modulating control of the actuator in response to standard control system signals including 4-20mA, Modbus, Direct AC control, and contact closure operation.

A few notable features include:

- Suitable for continuous operation in temperatures from -58º F to 185º F (-50° to 85° C).

- Provides unmatched control for any application from open/close to precision modulation

- Multiple, easy-to-use configuration methods including local pushbuttons, HART, Modbus RTU and RS 232 serial communications port standard on all DCM’s. An optional Modbus TCP interface is also available.

- Configurable stall and (optional) over-torque protection of the actuator and valve.

- Configurable full-stroke speed as fast as 7 seconds for 90 degrees travel

- Configurable control performance features including:

- Minimum positioning Stepsize down to 0.1 degree

- Full travel degrees rotation

- Configurable status LED’s

- Configurable alarming and alarm annunciation

- Stored actuator statistics and diagnostics

The Group 57’s non-wearing contactless position sensing technology will provide reliable control feedback for many years without any required maintenance.

- Sensor provides the DCM with a continuous feedback signal proportional to the position of the actuator’s output shaft.

- Utilizes magnetic vector sensing technology directly connected to the output shaft.

- No alignment or calibration required ever.

- A 4–20 mA position feedback signal is generated for remote indication.

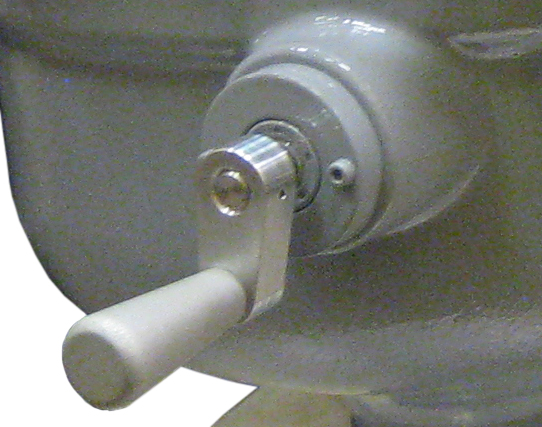

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics: