Group 75: Compact Part-Turn Rotary Actuator for Windbox Dampers

The Harold Beck Group 75 series (Model 75-100) provides a compact, high-precision solution for windbox damper control and small quarter-turn valve automation. Specifically engineered for space-constrained environments, this part-turn actuator delivers the same robust reliability and "set it and forget it" performance as our larger drives. By utilizing Beck’s unique no-burnout motor technology, the Group 75 eliminates the positioning drift and maintenance requirements of pneumatic drives, ensuring peak combustion efficiency and stable process control.

Designed for the extreme conditions of industrial boilers and furnaces, the Group 75 offers specialized high-temperature options to maintain absolute accuracy in intense thermal environments. The rugged NEMA 4X enclosure and maintenance-free gear train are optimized for high-cycle modulation, providing instantaneous response and zero-backlash positioning. Whether you are managing airflow or process fluids, the Group 75 provides a durable, energy-efficient motion control solution that maximizes facility uptime and reduces operating costs.

Compact Efficiency and Control Features:

- • Space-saving compact design optimized for windbox dampers and small valves.

- • High-temperature construction options available for extreme industrial heat.

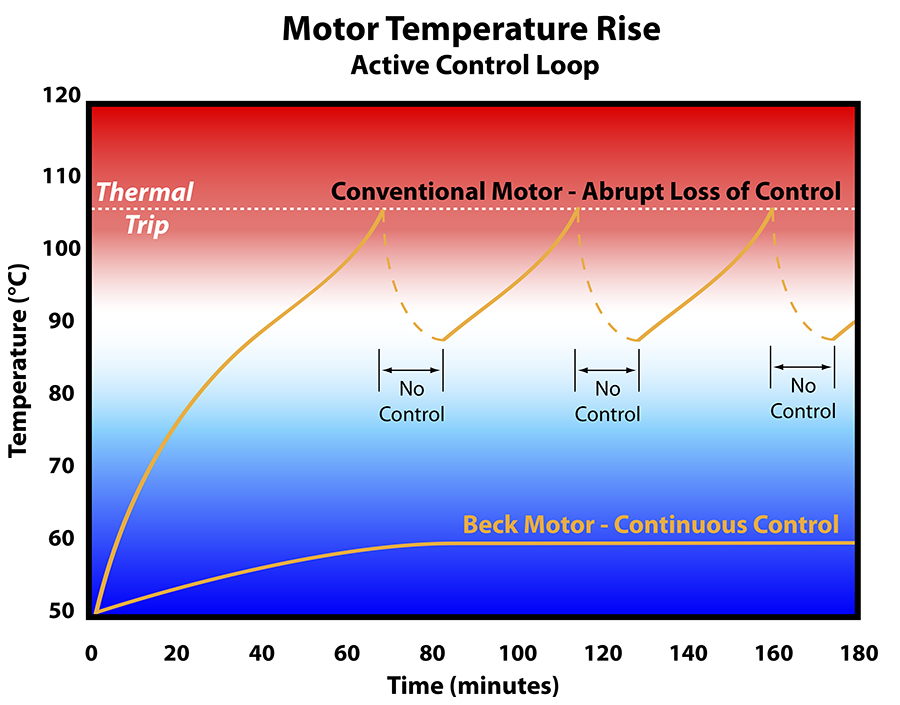

- • Continuous-duty motor prevents overheating during constant modulating cycles.

- • Precise quarter-turn positioning with zero-backlash for superior air and flow control.

- • Maintenance-free spur gear construction ensures long-life reliability and performance.

- • Weatherproof NEMA 4X aluminum housing for protection against dust and moisture.

AVAILABLE TORQUE AND TIMING COMBINATIONS FOR THE MODEL 75-100

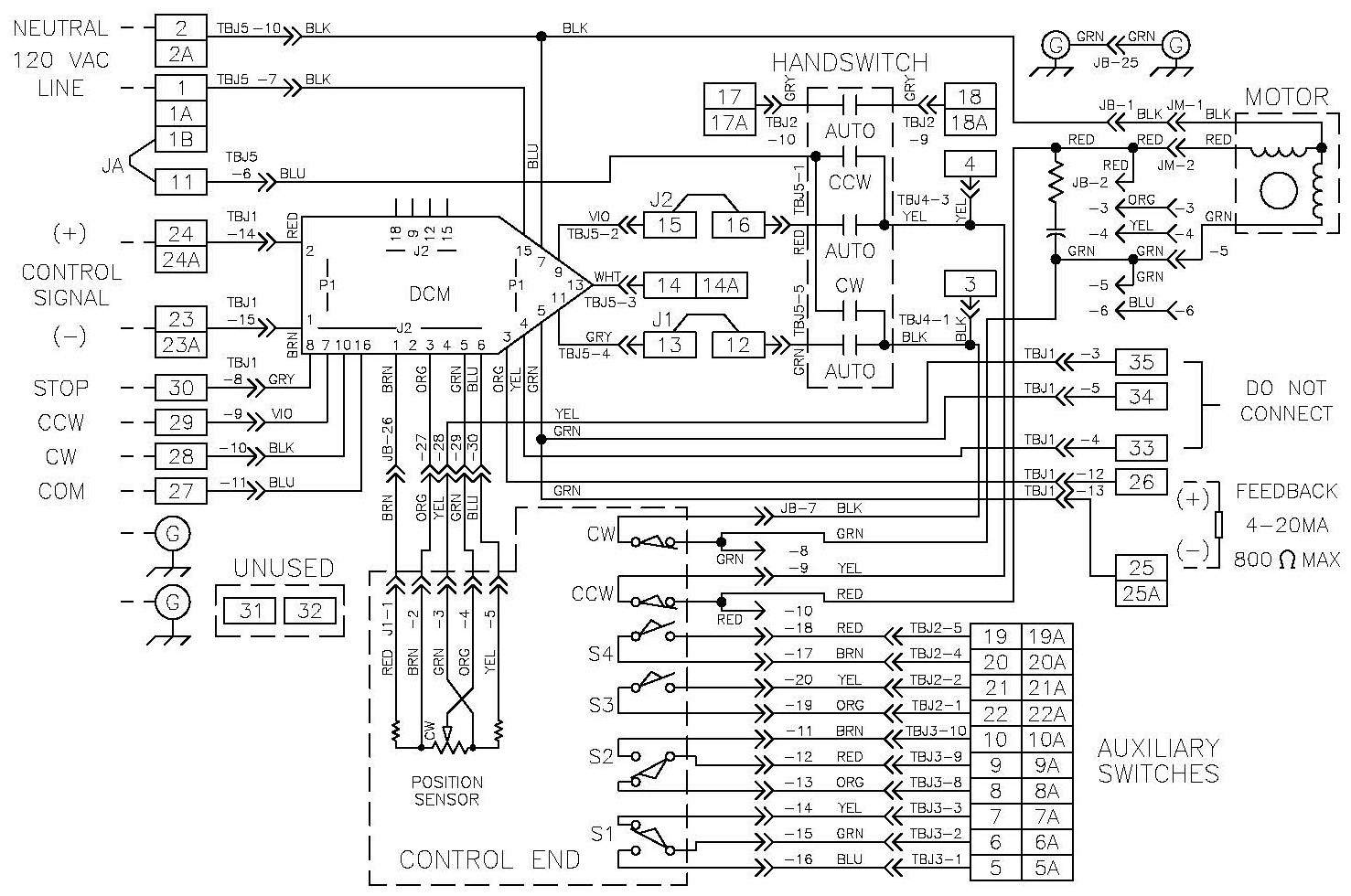

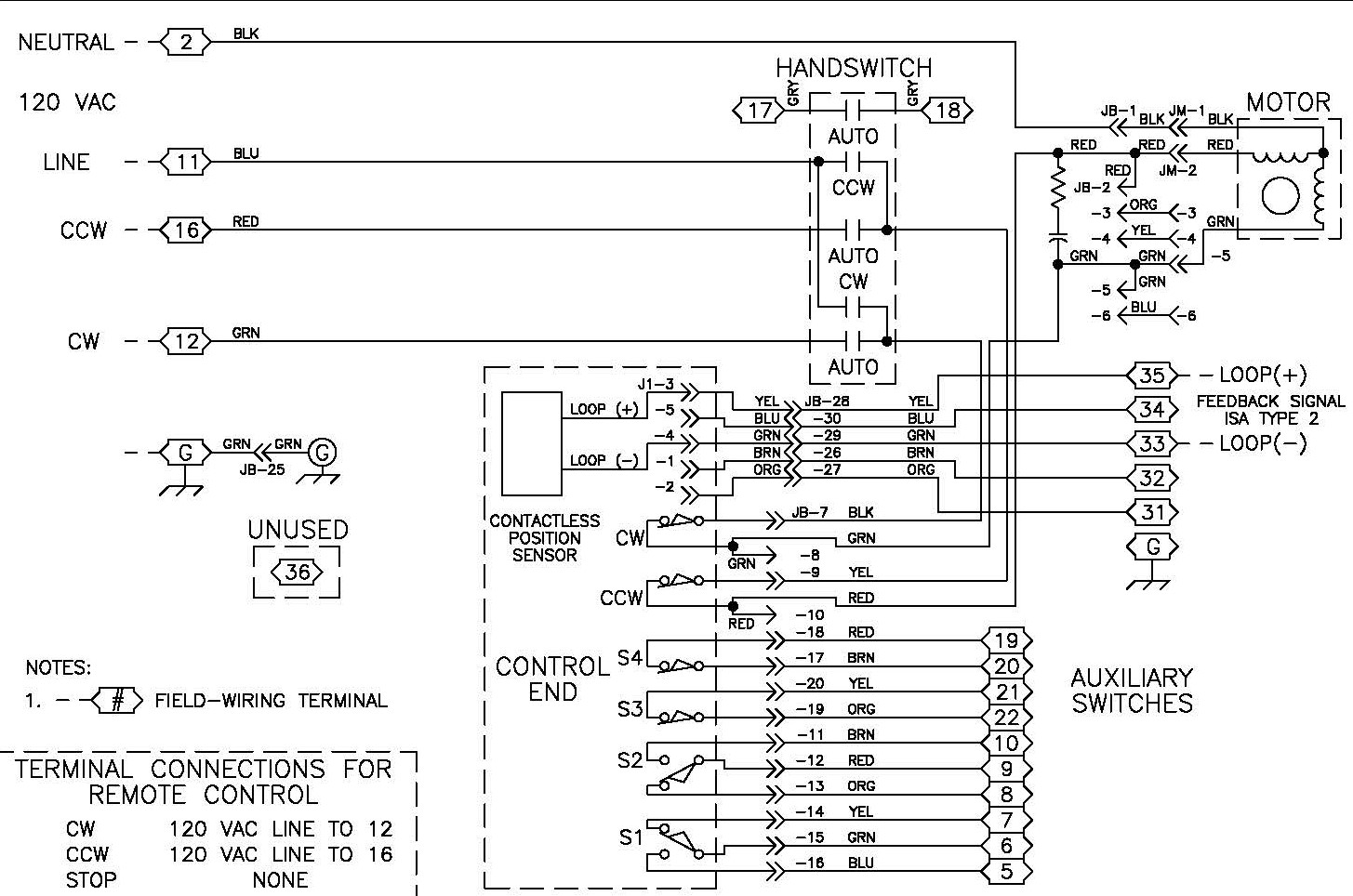

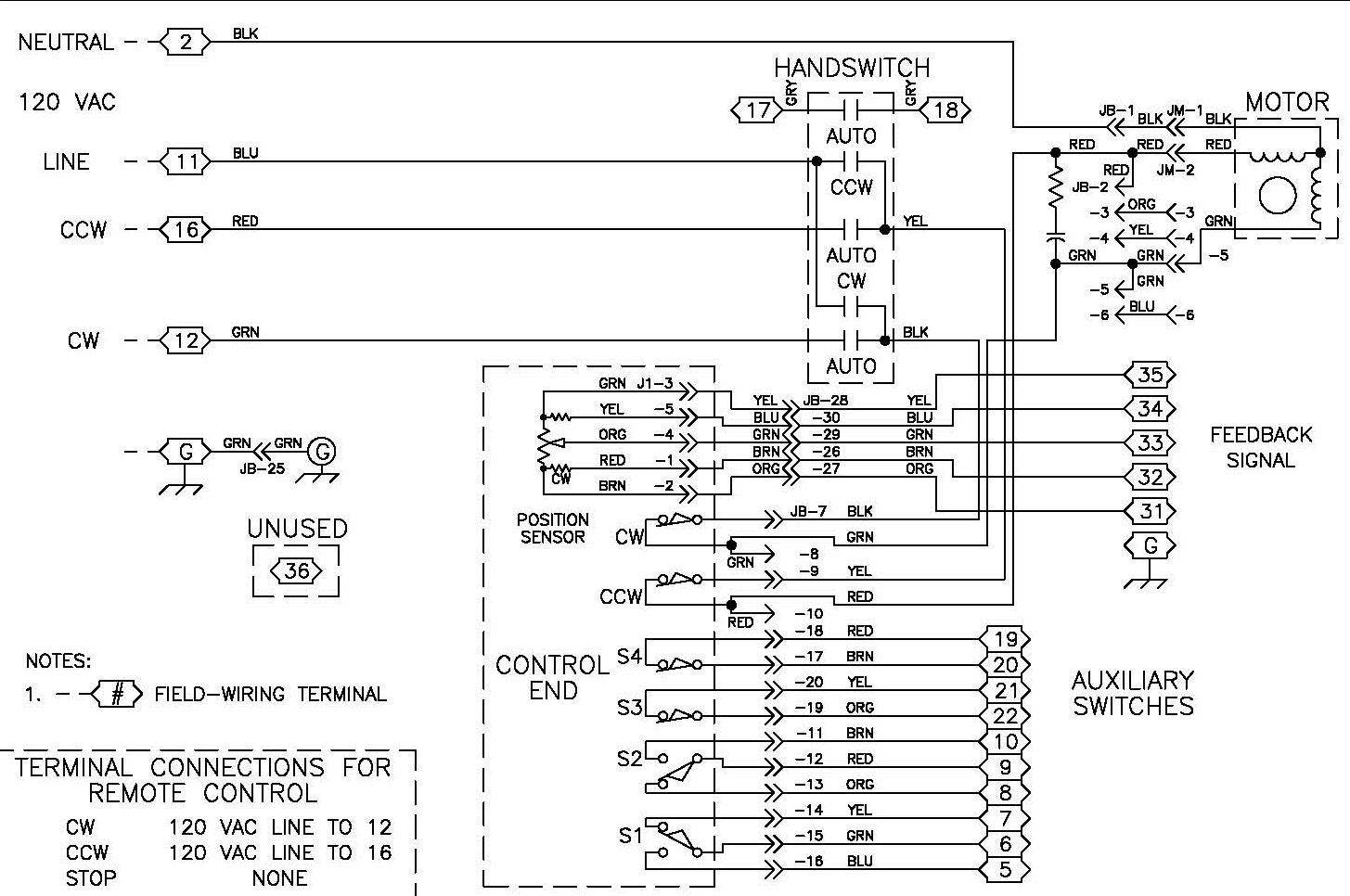

Beck’s DCM-3 provides modulating control of the drive in response to standard control system signals.

Notable features include:

-

- Convenient user interface for calibration and drive status.

- HART® compatibility.

- Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact

protection devices, relays, switches and reversing starters. - Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train.

</ul

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics: