Model 57-109: Class I Div 1 Fail-Safe Electric Actuator

The Harold Beck Model 57-109 is an explosion-proof electric actuator specifically designed for hazardous quarter-turn valve automation. Engineered for Class I, Division 1 environments, this unit provides unparalleled safety for volatile oil, gas, and petrochemical applications. A standout feature is the integrated on-board fail-safe backup power, which ensures your valves return to a predetermined safe position during a power outage, effectively protecting your facility and personnel from potentially dangerous process excursions.

The 57-109 offers exceptional versatility with both AC and DC power input options to fit any existing site infrastructure. This actuator combines Beck’s high-precision modulation with a rugged, flame-proof housing, allowing for stable and accurate flow control where safety is paramount. By utilizing a maintenance-free gear train and advanced diagnostic sensors, the Model 57-109 provides a cleaner, more reliable solution than pneumatic fail-safe systems, eliminating the need for frequent inspections and air-quality management in hazardous zones.

Hazardous Location and Safety Features:

- • Certified for Class I, Div 1 Hazardous Locations for safe operation in volatile areas.

- • On-board fail-safe backup power ensures guaranteed emergency valve positioning.

- • Flexible AC and DC power configurations to suit diverse industrial site requirements.

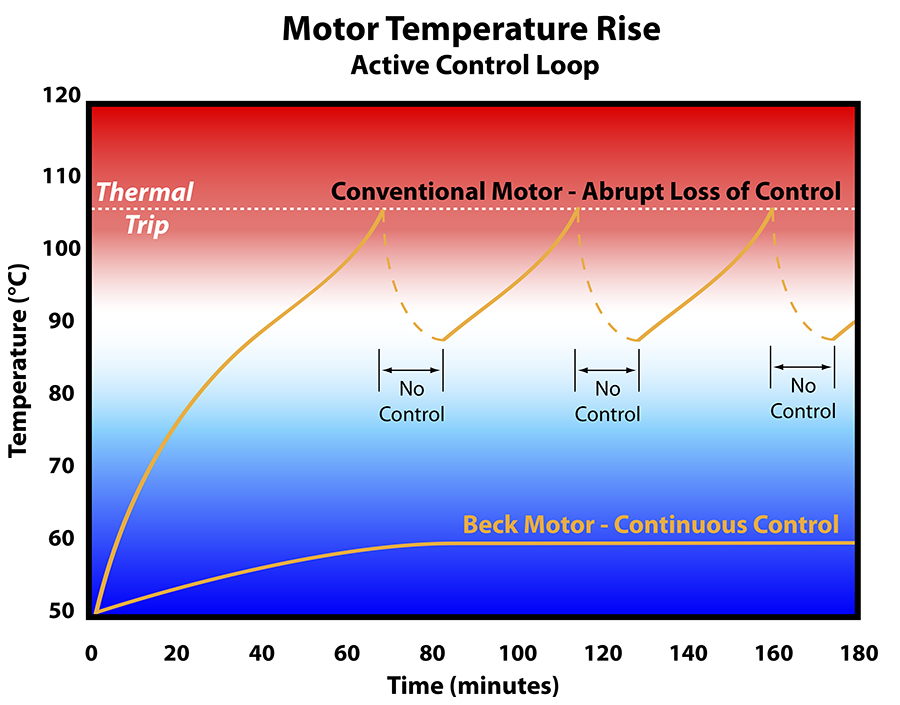

- • 100% duty cycle motor prevents overheating during high-frequency modulation.

- • Precision quarter-turn control for highly accurate flow, pressure, and process management.

- • Maintenance-free gear train and robust flame-proof enclosure for long-term reliability.

AVAILABLE TORQUE AND TIMING COMBINATIONS FOR THE MODEL 57-109

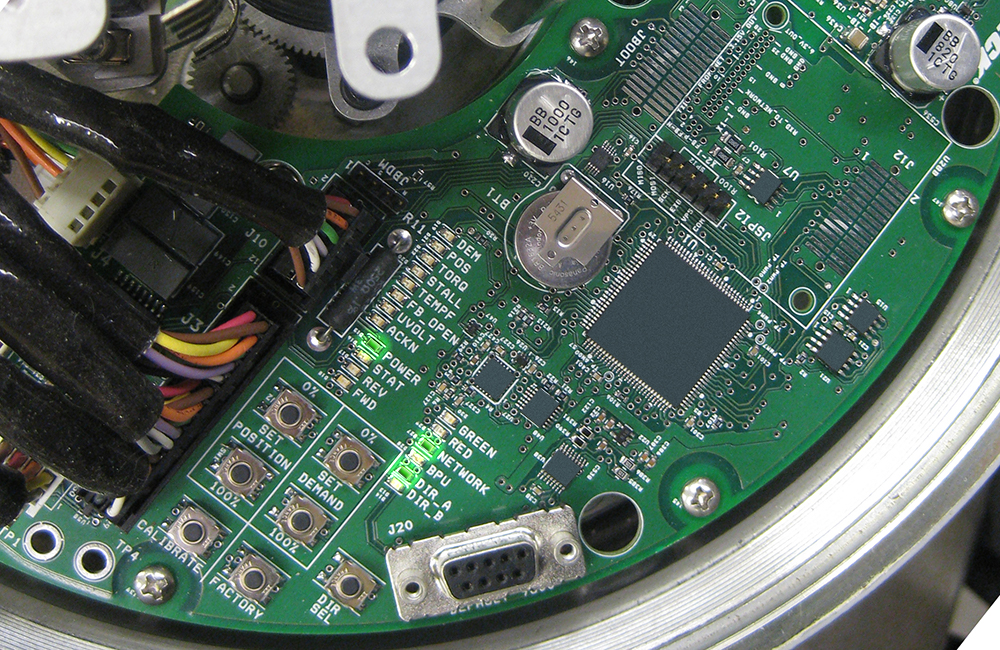

Beck’s DCM provides modulating control of the actuator in response to standard control system signals including 4-20mA, Modbus, Direct AC control, and contact closure operation.

A few notable features include:

- Suitable for continuous operation in temperatures from -58º F to 185º F (-50° to 85° C).

- Provides unmatched control for any application from open/close to precision modulation

- Multiple, easy-to-use configuration methods including local pushbuttons, HART, Modbus RTU and RS 232 serial communications port standard on all DCM’s. An optional Modbus TCP interface is also available.

- Configurable stall and (optional) over-torque protection of the actuator and valve.

- Configurable full-stroke speed as fast as 7 seconds for 90 degrees travel

- Configurable control performance features including:

- Minimum positioning Stepsize down to 0.1 degree

- Full travel degrees rotation

- Configurable status LED’s

- Configurable alarming and alarm annunciation

- Stored actuator statistics and diagnostics

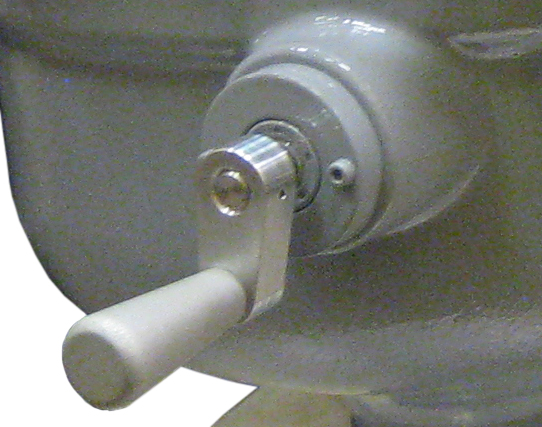

The Group 57’s non-wearing contactless position sensing technology will provide reliable control feedback for many years without any required maintenance.

- Sensor provides the DCM with a continuous feedback signal proportional to the position of the actuator’s output shaft.

- Utilizes magnetic vector sensing technology directly connected to the output shaft.

- No alignment or calibration required ever.

- A 4–20 mA position feedback signal is generated for remote indication.

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics: