Model 57-209: High-Torque Fail-Safe Hazardous Location Actuator

The Harold Beck Model 57-209 delivers high-torque, explosion-proof performance for quarter-turn valves in the world’s most demanding hazardous environments. Fully certified for Class I, Division 1 locations, this electric actuator provides a heavy-duty fail-safe solution for critical oil and gas process control. Featuring integrated on-board backup power, the 57-209 guarantees that valves return to a safe state during emergency power loss, offering a reliable alternative to complex and high-maintenance pneumatic or hydraulic fail-safe systems.

Versatility and intelligence are core to the 57-209, with AC/DC power compatibility and HART-ready diagnostics for real-time monitoring of actuator health. The ruggedized gear train and continuous-duty motor ensure absolute positioning accuracy and precision modulation even under high-load conditions. Housed in a flame-proof, weatherproof NEMA 4X enclosure, the Model 57-209 provides the maintenance-free safety and diagnostic intelligence required to optimize flow control and facility protection in volatile industrial atmospheres.

High-Torque Safety and Control Features:

- • High-torque output optimized for large quarter-turn valves in hazardous areas.

- • Class I, Div 1 certified explosion-proof design for volatile oil and gas environments.

- • Integrated fail-safe backup power ensures secure valve positioning during power loss.

- • Maintenance-free alloy steel gearing designed for high-cycle industrial modulation.

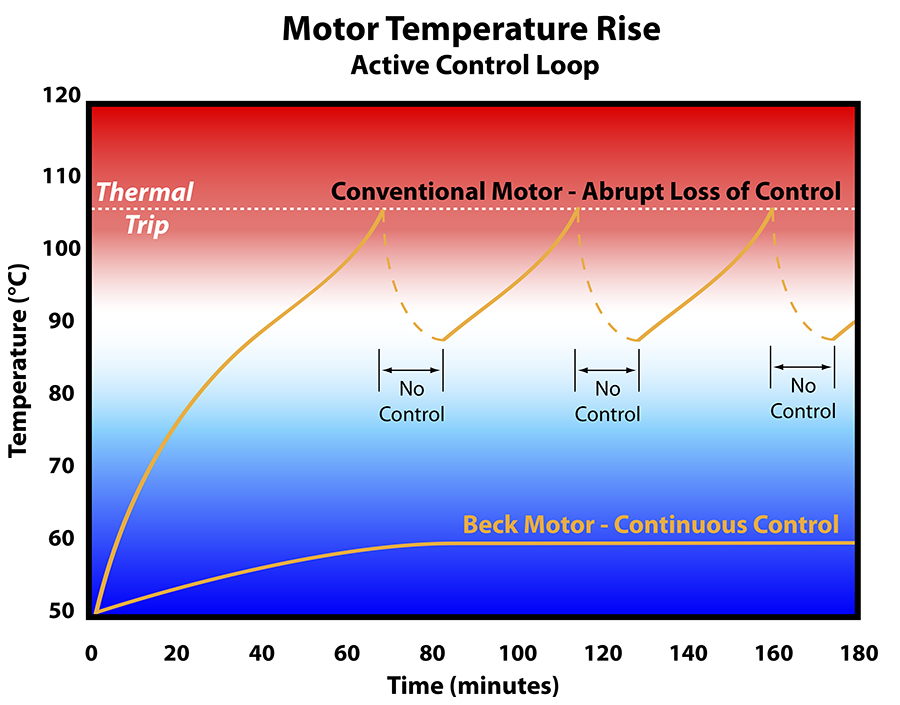

- • No-burnout motor technology allows for constant adjustment without thermal stress.

- • Advanced digital diagnostics and HART compatibility for superior asset management.

AVAILABLE TORQUE AND TIMING COMBINATIONS FOR THE MODEL 57-209

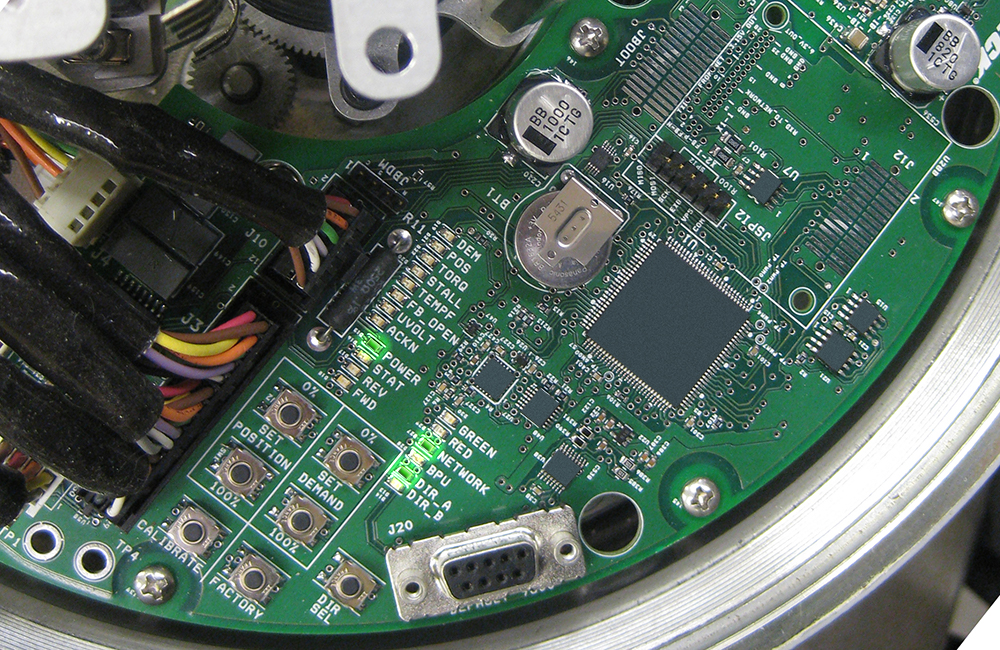

Beck’s DCM provides modulating control of the actuator in response to standard control system signals including 4-20mA, Modbus, Direct AC control, and contact closure operation.

A few notable features include:

- Suitable for continuous operation in temperatures from -58º F to 185º F (-50° to 85° C).

- Provides unmatched control for any application from open/close to precision modulation

- Multiple, easy-to-use configuration methods including local pushbuttons, HART, Modbus RTU and RS 232 serial communications port standard on all DCM’s. An optional Modbus TCP interface is also available.

- Configurable stall and (optional) over-torque protection of the actuator and valve.

- Configurable full-stroke speed as fast as 7 seconds for 90 degrees travel

- Configurable control performance features including:

- Minimum positioning Stepsize down to 0.1 degree

- Full travel degrees rotation

- Configurable status LED’s

- Configurable alarming and alarm annunciation

- Stored actuator statistics and diagnostics

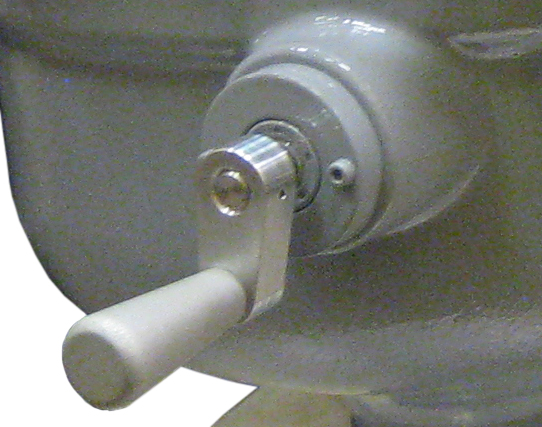

The Group 57’s non-wearing contactless position sensing technology will provide reliable control feedback for many years without any required maintenance.

- Sensor provides the DCM with a continuous feedback signal proportional to the position of the actuator’s output shaft.

- Utilizes magnetic vector sensing technology directly connected to the output shaft.

- No alignment or calibration required ever.

- A 4–20 mA position feedback signal is generated for remote indication.

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics: