Model 11-480: Industrial Multi-Turn Rotary Actuator for Stem Valve Automation

The Harold Beck Model 11-480 is a robust multi-turn actuator specifically designed for rising and non-rising stem applications in diverse process industries. As part of the proven Group 11 family, this actuator provides the precise, reliable positioning required to optimize control loops and enhance system efficiency. Its unique motor design reaches full speed and torque in less than 50 milliseconds and stops within 25 milliseconds, eliminating the dead-time and overshooting common in lower-quality electric actuators.

Equipped with the DCM-3 Digital Control Module and Beck’s patented CPS-5 contactless position sensor, the Model 11-480 offers infinite resolution and consistent feedback without the mechanical wear of potentiometers. The unit's heavy-duty, all-spur gear train is housed in a multi-compartment NEMA 4X aluminum enclosure, ensuring that sensitive electronics stay protected during installation and maintenance. With self-locking mechanics and a no-oil-bath design, the 11-480 provides a versatile and maintenance-free solution for any orientation.

Advanced Engineering Specifications:

- • Precise modulation with minimum step resolution of 0.1% to 0.25% of span.

- • Patented contactless position sensing (CPS-5) ensures accurate feedback with zero mechanical wear.

- • Durable alloy steel spur gear train with integral self-locking for secure position holding.

- • Multi-compartment NEMA 4X enclosure for superior protection and easy component access.

- • HART® compatibility and advanced diagnostics via the Digital Control Module (DCM-3).

- • Built-in stall protection and temperature sensing with configurable alarm functionality.

AVAILABLE TORQUE AND TIMING COMBINATIONS FOR THE MODEL 11-480

(LB-FT)

(SECONDS/90°)

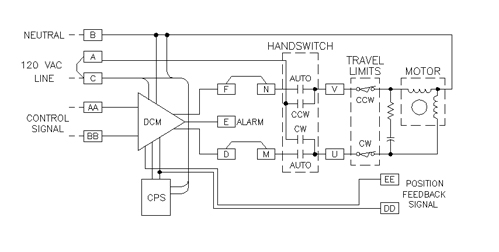

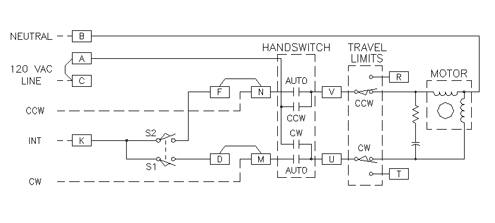

Beck’s DCM-3 provides modulating control of the drive in response to standard control system signals.

Notable features include:

- Convenient user interface for calibration and drive status.

- HART® compatibility.

- Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train.

Beck’s patented CPS-5 technology has been providing reliable control feedback with infinite resolution in our products for many years.

- Utilizes a unique ferrite magnetic design with no contacting or wiping surfaces to wear or intermittently lose contact.

- The ferrite rotor is driven directly by the output shaft through anti-backlash gearing.

- A 4–20 mA position feedback signal is available for remote indication.

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional Features available on Beck Control Electronics