Model 42-109: Precision High-Speed Linear Actuator

The Harold Beck Model 42-109 is a heavy-duty linear actuator engineered for rapid response and high-thrust industrial applications. This electric drive serves as a superior alternative to traditional pneumatic and hydraulic cylinders, offering precise, repeatable positioning without the need for constant maintenance or complex air systems. Designed for continuous modulation, the 42-109 features a proprietary no-burnout motor that can handle high-frequency starts and stops indefinitely, keeping your most critical processes running at peak efficiency.

Equipped with a high-efficiency precision ball screw and a rugged alloy steel gear train, the Model 42-109 maintains absolute accuracy even under maximum load conditions. The integration of advanced electronics and HART protocol compatibility allows for real-time health monitoring and easy field setup via a digital interface. With its weatherproof NEMA 4X housing and "set it and forget it" reliability, the 42-109 is the premier choice for mission-critical flow control and industrial automation where downtime is not an option.

High-Thrust Precision and Safety Features:

- • High-speed linear actuation with exceptional thrust for demanding motion tasks.

- • Precision ball screw assembly ensures smooth operation and minimal mechanical wear.

- • No-burnout motor technology allows for infinite modulation without duty-cycle limits.

- • Integrated HART-capable diagnostics for advanced asset management and troubleshooting.

- • Instantaneous response and non-coasting motor for absolute positioning accuracy.

- • Weatherproof NEMA 4X construction designed to withstand corrosive industrial settings.

AVAILABLE THRUST AND TIMING COMBINATIONS FOR THE MODEL 42-109

(LBF)

(INCHES)

(SECONDS/INCH)

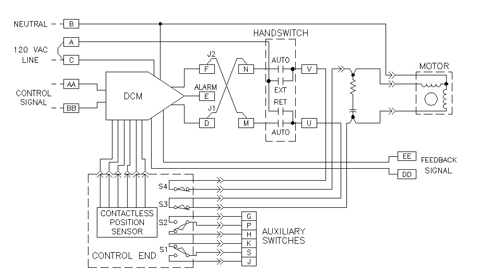

Electronics Used on Control Option 9

Beck’s DCM-2 provides modulating control in response to standard control system signals.

Notable features include:

- Convenient user interface for calibration and drive status.

- HART® compatibility.

- Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train.

Beck’s patented CPS technology has been providing reliable control feedback with infinite resolution in our products for many years.

- Utilizes a unique ferrite magnetic design with no contacting or wiping surfaces to wear or intermittently lose contact.

- The ferrite rotor is driven directly by the output shaft through anti-backlash gearing.

- A 4–20 mA position feedback signal is available for remote indication.

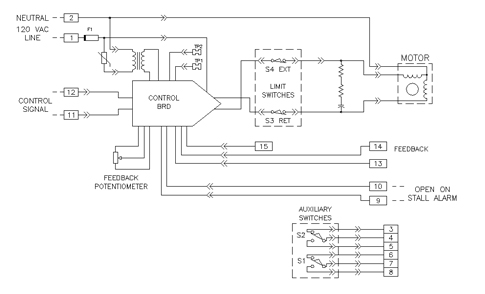

Electronics Used on Control Option 7

The 42-107 electronics package has a 4-20 mA modulating control board with position feedback.

The 42-107 has time-proven analog electronics on-board for simple, reliable, no-frills positioning and feedback of the drive.

A stall alarm contact and two auxiliary limit switches for position indication are integral features for the model 42-107.

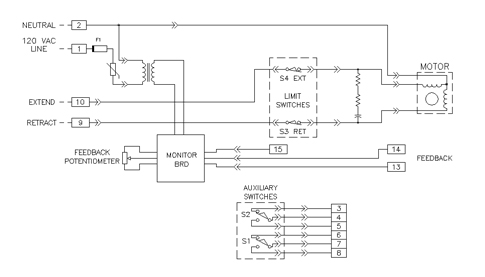

Electronics Used on Control Option 5

The 42-105 is equipped with similar analog electronics to the 42-107, but requires 120 VAC pulsed control instead of 4-20 mA. It allows direct AC control of the drive’s motor for either PAT type modulation or simple multi-position

control. The 42-105 provides a 4-20 mA position feedback and is equipped with two auxiliary limit switches for position indication.

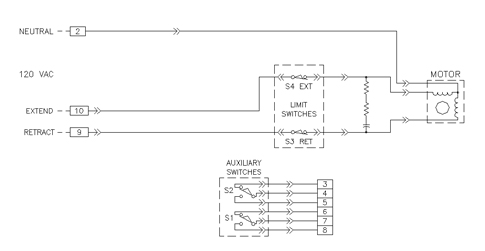

Electronics Used on Control Option 3

The 42-103 is intended for simple open/close operation. Direct AC to the motor will drive the unit to it fully open or fully closed position. Limit switches at each end of travel will stop the drive and may also be used for external

signaling.

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics