Model 22-409: Heavy-Duty Industrial Rotary Actuator

The Harold Beck Model 22-409 delivers maximum power and precision for the most demanding rotary applications in heavy industrial process control. Engineered to replace maintenance-intensive pneumatic and hydraulic systems, this high-torque electric actuator provides repeatable positioning accuracy for large dampers and flow control elements. Its rugged no-burnout motor is designed for infinite starts and stops, ensuring consistent performance in high-cycle environments without the risk of thermal degradation or positioning loss.

Equipped with an all-spur gear construction and a multi-compartment NEMA 4X aluminum housing, the Model 22-409 protects its internal mechanics and electronics from moisture and industrial contaminants. The actuator features a manual handwheel and electric handswitch for seamless local operation, alongside advanced digital electronics that provide isolated feedback and HART diagnostics. With Beck’s legendary reliability, the 22-409 maximizes facility uptime and reduces operating costs across the world’s most demanding industrial sites.

High-Torque Performance and Control Features:

- • Exceptional torque output for mission-critical industrial motion and flow control.

- • No-burnout motor technology enables 100% duty cycle without maintenance.

- • Durable alloy steel gearing ensures long-life reliability and prevents backlash.

- • Contactless position sensing for accurate, high-resolution feedback signals.

- • Ruggedized NEMA 4X construction for reliable performance in extreme conditions.

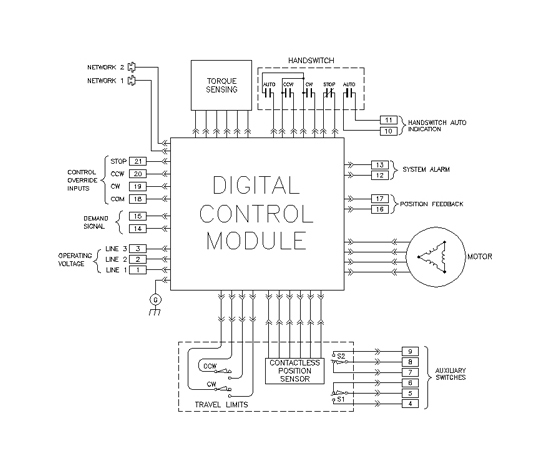

- • Digital Control Module (DCM) for intuitive calibration and smart diagnostic monitoring.

AVAILABLE TORQUE AND TIMING COMBINATIONS FOR THE MODEL 22-409

(LB-FT)

(SECONDS/100°)

Beck’s DCM-2 provides modulating control of the drive in response to standard control system signals.

Notable features include:

-

- Convenient user interface for calibration and drive status.

HART® compatibility. - Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train

- Convenient user interface for calibration and drive status.

.

Beck’s DCM-2 provides modulating control of the drive in response to standard control system signals.

Notable features include:

-

- Convenient user interface for calibration and drive status.

HART® compatibility. - Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train

- Convenient user interface for calibration and drive status.

.

Beck’s DCM-2 provides modulating control of the drive in response to standard control system signals.

Notable features include:

-

- Convenient user interface for calibration and drive status.

HART® compatibility. - Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train

- Convenient user interface for calibration and drive status.

.

Beck’s patented CPS technology has been providing reliable control feedback with infinite resolution in our products for many years

Notable features include:

-

- Utilizes a unique ferrite magnetic design with no contacting or wiping surfaces to wear or intermittently lose contact.

- The ferrite rotor is driven directly by the output shaft.

- A 4–20 mA position feedback signal is available for remote indication.

.

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics: