Model 22-809: Maximum Torque Industrial Rotary Actuator

The Harold Beck Model 22-809 is the premier solution for large-scale industrial applications requiring maximum rotary torque and absolute positioning precision. Specifically designed for massive dampers and heavy process control valves, this actuator eliminates the reliability issues and dead-time associated with large pneumatic cylinders. Its heavy-duty motor is rated for continuous modulation, providing the power and responsiveness needed to keep large industrial control loops perfectly synchronized under high-load conditions.

Built for the rigors of heavy industry, the Model 22-809 features a robust spur gear train and a weatherproof NEMA 4X enclosure that ensures maintenance-free operation for decades. The inclusion of a manual handwheel allows for local positioning during power outages, while patented contactless position sensing technology provides reliable feedback without mechanical wear. With advanced digital diagnostic tools and HART compatibility, the 22-809 offers the intelligence and power needed for high-uptime automation in the power, cement, and steel industries.

High-Torque Performance and Control Features:

- • Maximum torque output optimized for the largest industrial dampers and valves.

- • 100% duty cycle motor allows for constant, high-frequency modulation.

- • Maintenance-free gear train construction for extreme longevity and zero backlash.

- • Contactless position sensor (CPS) for wear-free, infinite-resolution feedback.

- • Rugged NEMA 4X construction protects internal components from harsh elements.

- • Isolated 4-20 mA feedback and HART protocol for modern digital control integration.

AVAILABLE TORQUE AND TIMING COMBINATIONS FOR THE MODEL 22-809

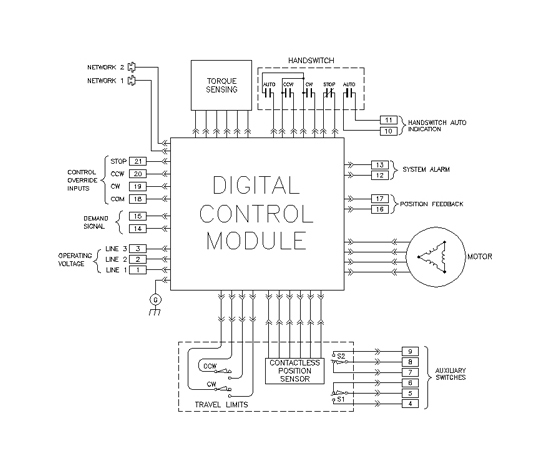

Beck’s DCM-2 provides modulating control of the drive in response to standard control system signals.

Notable features include:

-

- Convenient user interface for calibration and drive status.

HART® compatibility. - Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train

- Convenient user interface for calibration and drive status.

.

Beck’s DCM-2 provides modulating control of the drive in response to standard control system signals.

Notable features include:

-

- Convenient user interface for calibration and drive status.

HART® compatibility. - Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train

- Convenient user interface for calibration and drive status.

.

Beck’s DCM-2 provides modulating control of the drive in response to standard control system signals.

Notable features include:

-

- Convenient user interface for calibration and drive status.

HART® compatibility. - Compatible with common asset management systems.

- Receives control signals directly, eliminating the need for contact protection devices, relays, switches and reversing starters.

- Designed to operate continuously at temperatures from -40º F to 185º F (-40° to 85° C).

- Initiates shaft movement in steps ranging from 0.10% to 0.25% of span, depending on the timing of the gear train

- Convenient user interface for calibration and drive status.

.

Beck’s patented CPS technology has been providing reliable control feedback with infinite resolution in our products for many years

Notable features include:

-

- Utilizes a unique ferrite magnetic design with no contacting or wiping surfaces to wear or intermittently lose contact.

- The ferrite rotor is driven directly by the output shaft.

- A 4–20 mA position feedback signal is available for remote indication.

.

FACTORY CALIBRATION

All Beck drives are set-up and calibrated to the customer specification. No electrical adjustments are required before installation. Additional features available on Beck control electronics: